The Highmount Guy

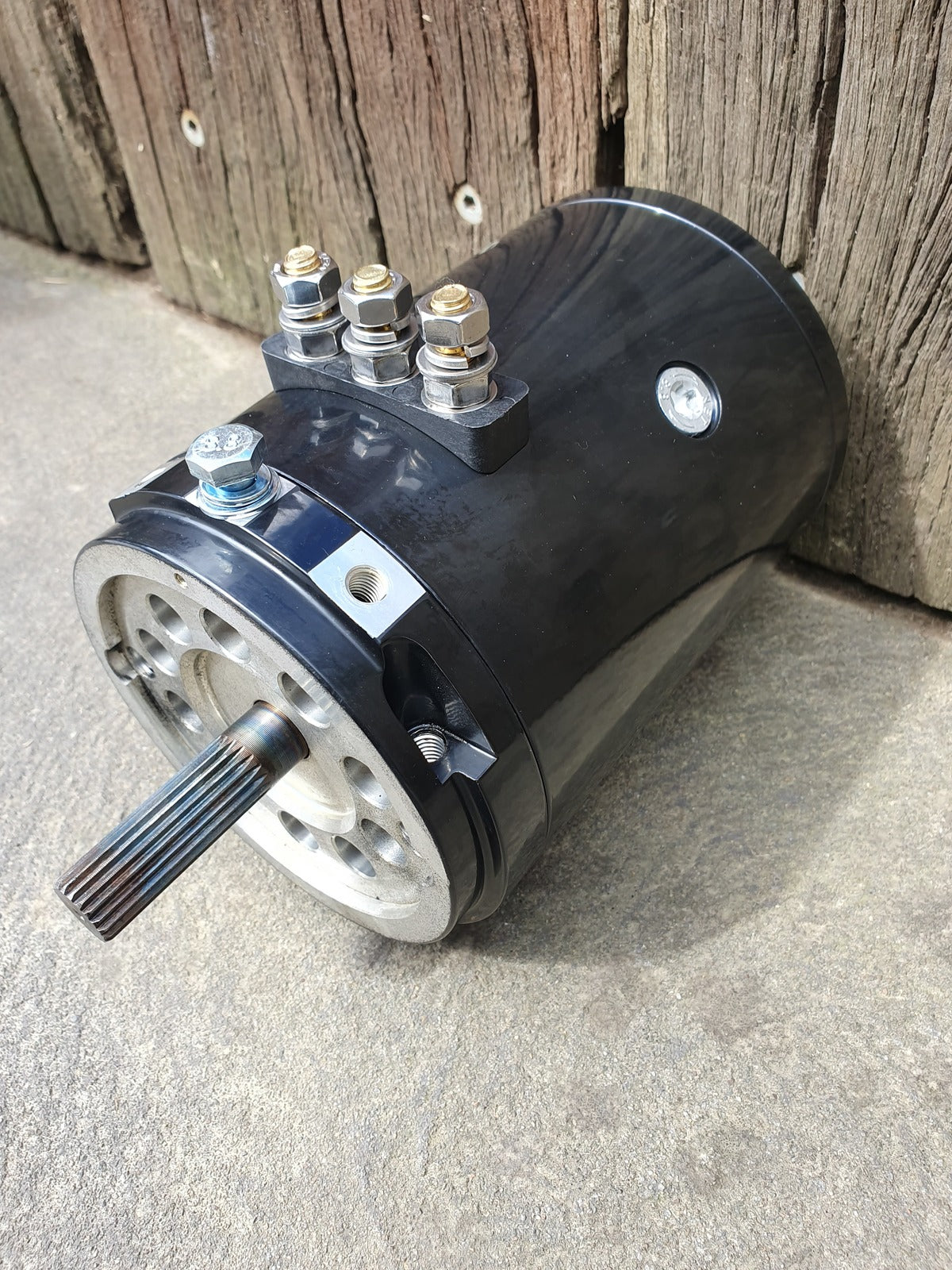

Red Winch OX Motor

Red Winch OX Motor

Couldn't load pickup availability

This motor has been developed and designed by RED Winches from the needs and wants of people into serious off-roading.

Under real world testing it has proven to be an exceptionally powerful motor, staying faster and stronger for longer.

This winch motor is the ultimate provider of power and speed for your winch.

Build features:

- Twin bearing setup (Front and Back)

- Heavy duty brush pack, for those that want to over-volt

- Dedicated mounting holes on the rear of the motor end plate for your motor solenoid

- Flat rear cover, allowing mounting of the motor solenoid easier

- High quality, robust commutator and brush setup

- More efficient design

The motor also benefits from a unique RED Winch designed quick release mechanism.

Allowing the motor to be changed quickly in the field should in the unlikely event you have a motor you need to change.

The motor can be swapped in 20-30secs easily, with no need to remove the motor solenoid or bus bars on top of the motor.

Saving crucial time when competing.

The OX motor can be fitted to all RED Winch products, apart from the Atom winch.

The OX Motor will not fit the original Hornet1 due to the centre distance between the motors on the Hornet1 but our new motor the Lynx will, see related products at the bottom of this page.

The OX Motor can fit winches that have traditional motors already fitted, like the the XP or BOW2, but some minor modifications might be needed due to the increased body diameter

It will fit to nearly all current competition winches, if unsure please email us to check if it will fit: sales@red-winches.com

It will fit onto your winch using either M6 location bosses (RED Winches, Storm Top Housing) or 1/4 UNC for WARN and non UK Winches.

For older Warn 8274 single motor top housing you will need the longer mounting studs.

Please specify mounting stud type in the configuration when ordering.

Spare studs can be ordered.

If you are after a motor control solenoid to control this motor, we also sell them, manufactured by Albright

The control voltage selection of an Albright solenoid (12v or 24v) is for the directional control voltage that will be used / applied to the 3 spade terminals on the front of the Albright.

The Albright power terminals on top can transmit 12v & 24v through them as standard.

MOTOR DATA

- Voltage: 12v

- Power: 7hp

- Torque: 16Nm

- No Load Speed: 11,800rpm

- Max Amp Draw: 438A

- Real World Testing Results

OVER VOLTING

This is a term used more frequently over the last few years, and many of the competition teams now do this to their motors and winch setup.

This is where you apply 24vDC power to a 12vDC rated motor. This is known as “Overvolting”.

The OX Motor can be “Overvolted”, but comes with warnings and operational guides, as shown below:

- The manufacture does not recommend doing this, as it puts extra load and speed into the motor it was not designed for.

- “Overvolted” motors are not covered by any warranty, claims for motor damage can be investigated but not supported in competition use.

- “Overvolted” motors must be maintained and serviced regularly, at least every 3 Events.

- “Overvolted” motors must not be run continuously under no load conditions (winding rope in or our), the longer they are run the faster they will go, too fast and they can go above 20,000rpm and mechanical damage will occur at this speed. When little or no load is on the motors, always operate the motors in short bursts. Bursts can be 10-15m or rope a time onto the drum.

- “Overvolted” motors still draw the same AMPS as non-overvolted motors. 12v on 12v = 24v on 12v, some people think the AMPS are halved, they are not. Your winch can draw 900A in an extreme pull with a twin motor setup. So be warned, make sure all the electrical elements in your winch system can support and cope with this level of AMP draw.

**Busbar kits and covers are available separately**